We can help you stay profitable in an increasingly competitive industry!

As media and communications continue migrating from "ink on paper" to digital platforms, the pulp and paper industry is clearly in a period of shifting markets. While printing is in a decline, manufacturing is rising in many emerging markets, driving an increasing global demand for paper used in product packaging. Demand for paper hygiene and cleaning products is also expected to grow in coming years. At the same time, paper products are now being exported from all over the world, so competition has gotten more intense.

As media and communications continue migrating from "ink on paper" to digital platforms, the pulp and paper industry is clearly in a period of shifting markets. While printing is in a decline, manufacturing is rising in many emerging markets, driving an increasing global demand for paper used in product packaging. Demand for paper hygiene and cleaning products is also expected to grow in coming years. At the same time, paper products are now being exported from all over the world, so competition has gotten more intense.

The biggest challenge for the pulp and paper industry is managing the wide variety of bulk materials, which can range from wet and sticky slurry to loose, dry material like sawdust or loose waste paper. Primarily, plant managers deal with fugitive material and runaway dust issues. Transporting wet material in pulp or slurry form sticks easily to the conveyor belts and gets carried back to the tail pulley, potentially jamming or damaging the equipment. Meanwhile, dry material, like wood chips or bark, is lighter in weight and is more prone to spilling off the belt. Dust is also a problem at pulp and paper plants because it can be inhaled by workers, causing health problems, and can even ignite and cause an explosion.

At Martin Engineering, we manufacture durable equipment that keeps raw wood, wood chips, wood pulp, slurry and recycled waste paper on the conveyor belts better than any other product on the market. We are known throughout the world for the durability and cost effectiveness of our belt cleaning solutions, which eliminate carryback problems when working with sticky, resinous substances. Plus, we provide innovative transfer point solutions that stabilise your belts, minimise fugitive materials and contain runaway dust.

We also offer a wide range of flow aid and vibration products that eliminate flow problems in silos, hoppers, chutes and trailers. So whether you’re transporting wood or wood pulp as a fuel source for power generation, or as part of a paper production process, we are dedicated to helping you transport it as efficiently as possible.

Our professional engineers and technicians love to talk shop, so give us a call and let’s chat about your plant’s operations, your challenges and how we can solve them. We have many customers in the pulp and paper industry so, whatever your specific problem is, we’ve probably seen it. And if we’ve seen it, we’ve solved it. Because that’s what we do every day!

- Move material more efficiently along conveyor systems and minimize carryback

- Keep downtime for maintenance and belt cleaning to a minimum

- Reduce spillage and dust problems by keeping conveyor belts aligned

- Prevent material from spilling off of moving conveyor belts

- Manage airborne dust and minimize the risk of explosion and inhalation

- Eliminate the need for workers to enter confined spaces

- Deliver more product by maximizing your plant’s overall throughput

- Reduce costs by minimizing waste and reducing energy consumption

- Eliminate excessive downtime for maintenance and cleanup

Martin® Air Cannons Maintain Boiler Feed Rate At Power Plant

Transfer Point Solutions Increase Productivity At Container Board Plant

XHV Air Cannons Unplug Wet Bark At Paper Manufacturer

Dust Bags Filtrate Bark Dust At Paper Plant

Paper Plant Having Trouble With Fugitive Material

Free Engineering and Application Assistance

Our technicians have solved problems for people in your industry all over the world. Take advantage of our wealth of knowledge. Tell us about your situation today to learn how Martin can improve your performance, safety and bottom line - with no obligation. We want to ensure that you choose the right solution for your exact needs and we are willing to invest the time upfront to get it right the first time.

Contact Us Now

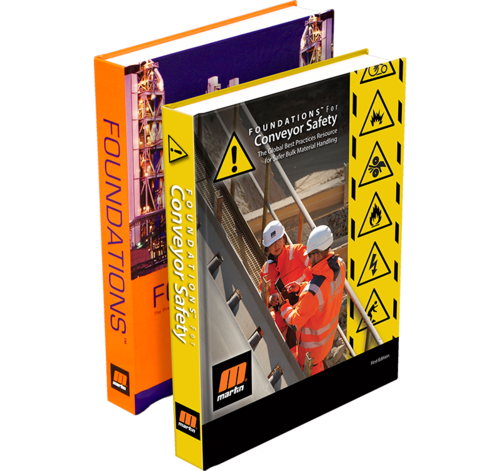

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy

Save With Our Martin® Walk the Belt™ Service!

Every conveyor is different, even within the same facility! We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. Immediate data and photos will be available to facility managers and our suggestions will ensure long-term savings and efficiency.

Get Your Belts Reviewed By People Who Know What They’re Looking At -- At No Charge!