Belt Cleaners That Clean Better, Last Longer, Cost Less.

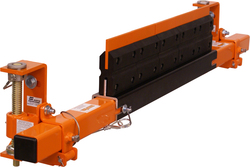

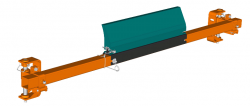

High-performing belt cleaners keep belts clean, eliminating carryback and making conveyor systems safer and more productive. At Martin Engineering, we offer belt cleaners that work with all belt sizes and speeds, regardless of industry or type of material. We also offer belt cleaners that work in the most challenging and unique environments, such as on conveyor systems where there’s minimal space around the head pulley.

Our speciality belt cleaners include conveyor belt washing systems, belt brush cleaners, food-grade belt scrapers, water cleaners and high-temperature cleaners, all engineered for challenging conditions and unusual materials.

Keeping belts clean is more than just a matter of cleanliness. Installing high-quality Martin® Belt Cleaners substantially improves efficiency by providing the following benefits:

- Increased profitability - Eliminating carryback reduces fugitive material and minimises the cost of unnecessary cleanup and maintenance.

- Less material loss - By scraping the belts clean at the head pulley, belt cleaners eliminate carryback and keep bulk materials moving in the right direction through transfer points or into containers.

- Longer lasting conveyor equipment - Material that is carried back under the belt often ends up inside the conveyor system and can damage rollers and idlers while causing belts to wander and fray.

- Lower energy costs - When material sticks to the belt beyond the head pulley, the added weight of the material stuck to the belt makes the equipment work harder so it uses more energy.

- Safer work environment - When fugitive material accumulates under the belt, workers can easily slip and fall trying to walk through the mess. Plus, uncontained dust can cause health problems when inhaled and can ignite causing a deadly explosion.

- Reduced dust problems - Fugitive dust is frequently a by-product of material that falls from under the belt on the return trip.

Industry Applications For Belt Cleaners:

- Reduce time spent cleaning up fugitive material

- Eliminate downtime for unscheduled equipment maintenance

- Minimize lost material

- Reduce the risk of slip-and-fall accidents around belts

- Minimize the amount of respirable dust to which workers are exposed

- Eliminate the risk of dust explosions

- Increase revenues through optimized production

- Reduce maintenance and belt cleanup costs

- Spend less on energy consumption caused by inefficiency

Free Engineering and Application Assistance

Our technicians have solved problems for people in your industry all over the world. Take advantage of our wealth of knowledge. Tell us about your situation today to learn how Martin can improve your performance, safety and bottom line - with no obligation. We want to ensure that you choose the right solution for your exact needs and we are willing to invest the time upfront to get it right the first time.

Contact Us Now

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy

Save With Our Martin® Walk the Belt™ Service!

Every conveyor is different, even within the same facility! We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. Immediate data and photos will be available to facility managers and our suggestions will ensure long-term savings and efficiency.

Get Your Belts Reviewed By People Who Know What They’re Looking At -- At No Charge!