Lower costs and higher efficiency means more profits… we can help!

For recycling companies, changing economic conditions around the world are making it more and more difficult to turn a profit. It’s the law of supply and demand and, sure, as more and more consumers have gotten used to recycling household waste, the supply of paper, plastics, metal and glass has expanded. At the same time, however, fluctuations in currency and a cooling Chinese economy have reduced demand, squeezing revenues and profits.

For recycling companies, changing economic conditions around the world are making it more and more difficult to turn a profit. It’s the law of supply and demand and, sure, as more and more consumers have gotten used to recycling household waste, the supply of paper, plastics, metal and glass has expanded. At the same time, however, fluctuations in currency and a cooling Chinese economy have reduced demand, squeezing revenues and profits.

While prices have dropped, the cost of processing recyclables hasn’t. In fact, for companies in sustainable materials management (formerly classified as “municipal waste” by the Environmental Protection Agency) the cost of the recycling equipment, manpower and energy required to move all that material has actually gone up because consumers are putting increasing amounts of non-recyclables – like plastic garbage bags – into the stream. This can clog up processing equipment, including conveyor belts and hoppers, and cause unexpected shutdowns.

High-quality, durable solutions that will improve your conveyor belt operation.

High-quality, durable solutions that will improve your conveyor belt operation.

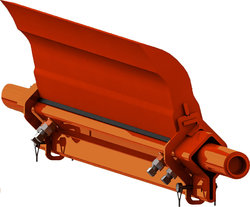

At Martin Engineering, we have a 70-year history of manufacturing high-quality equipment designed specifically to keep materials – like recyclables and waste – flowing efficiently. And because waste and recycling plants move large volumes of material that vary greatly, from household waste and organic byproducts to construction waste, your equipment has to accommodate a wide range of conditions. Whether your flow stream is being moved along by a conveyor system, into and out of a hopper or truck bed, or down a chute and through an unloading port, we have developed products that prevent obstructions from accumulating in turns and bottlenecks.

We are a global leader in providing flow aids like industrial vibrators and air cannons that keep material from sticking to the sides of containers and chutes and obstructing its movement through the process. Plus, we offer the most efficient belt cleaners on the market, eliminating the carryback that can travel with the belt back into the tail pulley and potentially damage your equipment.

So pick up the phone and call one of our professional engineers or technicians. We enjoy talking shop and would love to hear about your operation, the challenges you face and what you’ve already tried as a solution. With the amount of experience we have under our belts, it’s pretty likely we’ve dealt with it before. And if not, we’re always up for a new challenge!

- Keep downtime for maintenance and housekeeping to a minimum

- Move recycled material more efficiently through the process

- Reduce spillage and equipment damage by keeping conveyor belts clean

- Prevent material from spilling off of moving conveyor belts

- Eliminate the need for workers to enter confined spaces

- Manage airborne dust and minimize the risk of inhalation and explosion

- Deliver more product by maximizing overall throughput

- Eliminate excessive downtime for conveyor belt maintenance and cleanup

- Reduce costs by minimizing waste and reducing energy consumption

Recycling Plant Experiencing Impact Damage And Belt Misalignment

Martin® Belt Cleaners Save Client Over $55,000 Per Year

Martin Program Offers Hispanic Workers Advanced Training

Free Engineering and Application Assistance

Our technicians have solved problems for people in your industry all over the world. Take advantage of our wealth of knowledge. Tell us about your situation today to learn how Martin can improve your performance, safety and bottom line - with no obligation. We want to ensure that you choose the right solution for your exact needs and we are willing to invest the time upfront to get it right the first time.

Contact Us Now

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy

Save With Our Martin® Walk the Belt™ Service!

Every conveyor is different, even within the same facility! We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. Immediate data and photos will be available to facility managers and our suggestions will ensure long-term savings and efficiency.

Get Your Belts Reviewed By People Who Know What They’re Looking At -- At No Charge!