Foundations™ Operations & Maintenance Workshop Dramatically Improves Productivity

A cement plant in Colombia was experiencing severe spillage issues on several of its conveyors, causing belt misalignment and damage to the belt and rolling components. The situation increased maintenance costs, due to premature replacement of the belt and conveyor components, as well as the labor expense of three people for a full shift each.

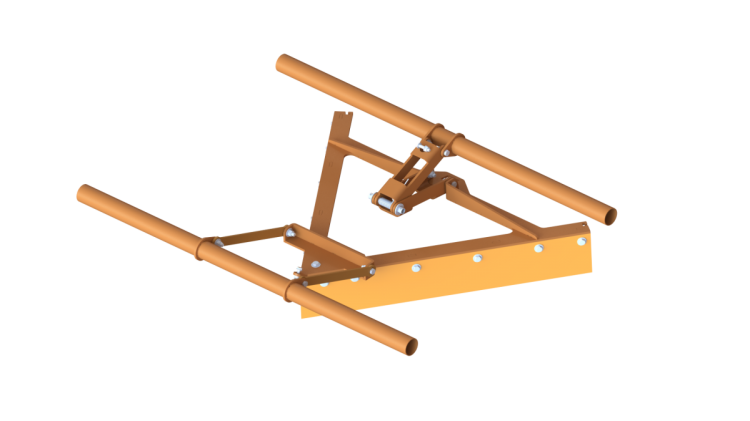

New VPlow Prevents Conveyor Belt Damage

Luminant Sandow handles 31,200 tons of lignite per month. The plant had an existing v-plow installed, at one point, which allowed the nose of the plow to dip down from wear or belt slack. When the nose would dip, the plow would dig into the belt, causing belt damage and even ripping of the belt. This problem cost the plant $26,000 plus labor.

Martin Saves Cement Plant $5,000 Per Month In Labor And Equipment

A plant was experiencing major problems with dust and material spillage on their crusher discharge belt coming from the quarry. This required clean up a minimum of once every week. It was also causing premature failure and belt wear due to idlers freezing up. The plant estimated this problem was costing $5,000 per month in labor and equipment costs.